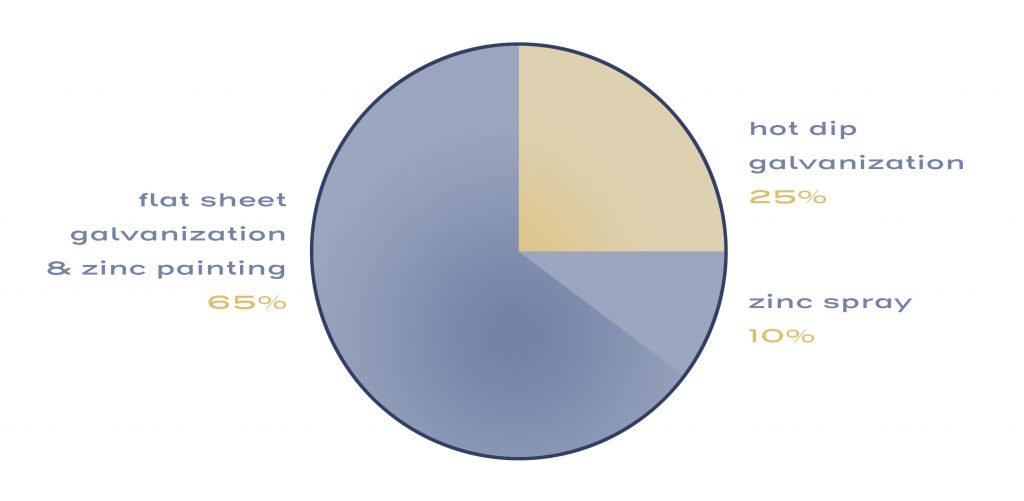

Hot dip galvanization, zinc spraying, and zinc painting have been applied since years onto steel as protection against corrosion or decorative coating. The PVDG technology developed by AG2, which uses a combination of evaporation and plasma, offers an advantageous alternative in terms of material and energy savings as well as coating quality to these three classical techniques. The inline PVDG coaters provided by AG2 are flexible with a very high throughput which has the advantage to reduce costs of ownership and offer superior coating properties. The plasma technology is recognized as an environmental friendly technology.

The usage of the PVDG technology does not require special governmental authorizations. The systems are built to meet the CE-norms. The modular design and the easy assembly of the system offer to the user the possibility to move the plant from one location to another allowing high flexibility in response to customer’s needs. The system is fully automated and requires only one person to operate. The zinc usage is limited to the amount just needed for the coating. AG2 delivers turnkey PVDG production lines adapted to meet specific customer needs.